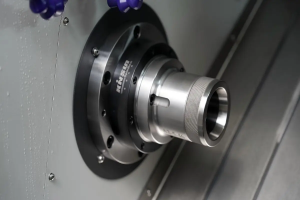

At Leichman, a distinguished sub-brand of Hoston, we are dedicated to delivering cutting-edge CNC machining solutions tailored specifically for the medical industry. Our commitment to precision and quality ensures that we meet the rigorous standards required in healthcare manufacturing. By focusing on CNC machining solutions for medical applications, we have positioned ourselves as a trusted partner for medical device manufacturers.

Understanding CNC Machining Solutions for Medical Devices

CNC machining solutions are revolutionizing the medical field by providing the ability to manufacture complex and intricate components with unparalleled accuracy. These solutions utilize computer-controlled machines to produce parts that are essential for a wide range of medical devices. At Leichman, we understand the importance of precision in medical applications, where even the smallest deviation can lead to significant consequences.

Types of CNC Machining Solutions in Medical Applications

- Surgical Instruments

One of the primary applications of CNC machining solutions in the medical industry is the production of surgical instruments. These instruments require high levels of precision and durability, and our advanced CNC machines are capable of meeting these demands. We offer CNC machining solutions for medical instruments that include everything from scalpels to forceps, ensuring that each tool is manufactured to the highest standards of quality and performance.

- Implants and Prosthetics

Another critical area where our CNC machining solutions excel is in the production of implants and prosthetics. These components must be tailored to fit individual patients while maintaining structural integrity and biocompatibility. At Leichman, we utilize advanced CNC machining techniques to create custom implants that meet the specific needs of healthcare providers and their patients. Our CNC machining solutions for medical implants ensure a perfect fit and optimal functionality.

- Diagnostic Equipment Components

CNC machining solutions are also essential in the manufacturing of diagnostic equipment components. From housings to internal mechanisms, precision is key in ensuring that diagnostic devices operate correctly. We take pride in offering CNC machining solutions for medical diagnostic equipment that enhance accuracy and reliability. Our commitment to quality ensures that each component we produce contributes to the effective functioning of critical medical devices.

Conclusion

In the rapidly evolving medical industry, the need for reliable and precise CNC machining solutions is more important than ever. At Leichman, we are committed to providing CNC machining solutions for medical applications that meet the highest standards of quality and performance. Whether it’s surgical instruments, implants, or diagnostic equipment components, our advanced machining capabilities ensure that we deliver exceptional products to our clients. Partnering with Leichman means choosing a leader in CNC machining technology, dedicated to supporting the medical field with innovative solutions that enhance patient care.