The demand for complex, high-precision parts is growing rapidly in modern manufacturing. Industries like aerospace and medical devices require components that push the limits of geometry and tolerance. To meet these rigorous standards, manufacturers need equipment that offers more than just basic cutting capabilities. This is where a 5–axis machining center becomes essential. At Leichman, we understand that a 5-axis machining center is not just a tool; it is a strategic asset for producing intricate 3D shapes with incredible accuracy. By allowing the cutting tool to approach the workpiece from virtually any direction, a 5-axis machining center ensures that even the most difficult designs become a reality.

What Is a 5 Axis Machining Center?

To understand the value we provide, it is helpful to first define the technology. A standard 3-axis machine moves a tool along the X, Y, and Z linear axes. A five-axis machine, however, adds two rotary axes—typically A and B, or B and C. These additional axes allow the cutting tool or the workpiece to tilt and rotate. This movement enables the cutter to maintain optimal contact with the part at all times.

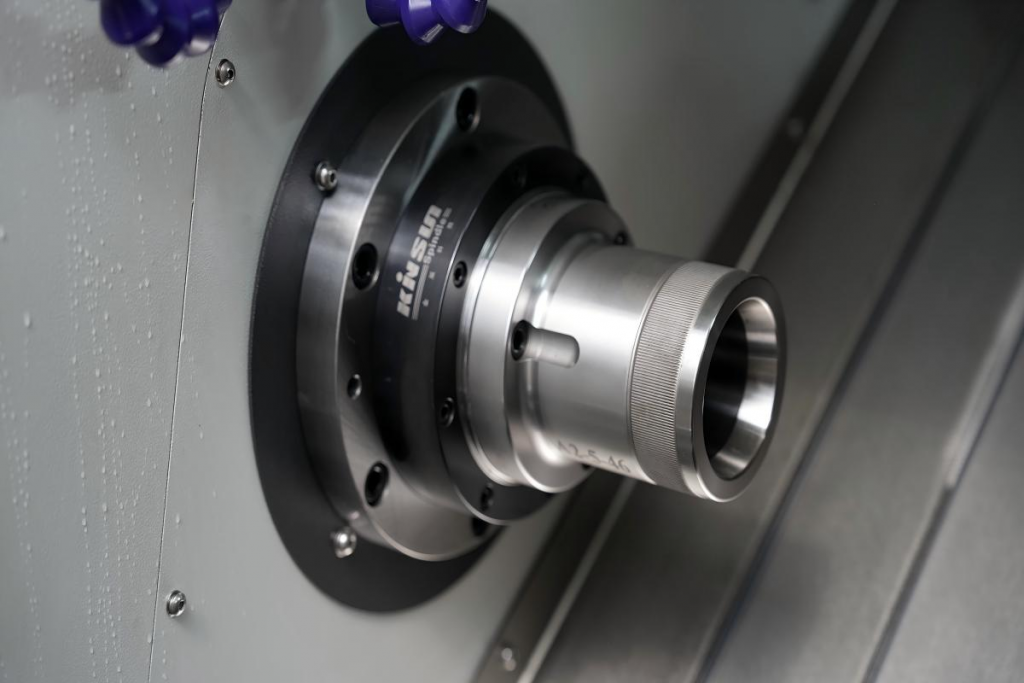

There are different configurations of this technology. The most common types include the trunnion table, where the table tilts and rotates, and the swivel head style, where the spindle moves. We also see large gantry designs for massive components. Whether you use a compact 5-axis milling machine or a larger gantry system, the goal remains the same: accessing five sides of a prismatic part in a single setup.

The Critical Need for 5-Axis in High-Stakes Industries

We see the greatest impact of this technology in sectors where failure is not an option. Aerospace and medical manufacturing present unique challenges that traditional 3-axis machining simply cannot handle efficiently.

Aerospace Challenges

In the aerospace sector, weight reduction and structural integrity are paramount. Manufacturers often work with difficult-to-machine materials like Titanium and Inconel. We frequently see requirements for parts such as blisks (blade-integrated disks), impellers, and complex airframe structures.

The main pain point here is maintaining aerodynamic profiles. A turbine blade, for example, has a complex curved surface that changes constantly along its length. A standard machine would require incredibly long process times and multiple setups to approximate these curves. A five-axis cnc machine allows the cutter to follow the curvature of the blade smoothly. This results in a superior surface finish and ensures the aerodynamic properties remain intact.

Medical Device Challenges

The medical industry faces a different set of hurdles. Here, the focus is on biocompatibility and human anatomy. Manufacturers use materials like Titanium, Cobalt Chrome, and PEEK to create joint replacements (knees and hips) and surgical instruments.

The challenge is that the human body does not have straight lines. Bone screws and implants must feature organic, free-form surfaces to match human anatomy perfectly. A five-axis cnc machine excels here by contouring these organic shapes precisely. This precision ensures that an implant fits correctly, which is vital for patient recovery.

The 5-Axis Advantage: One-and-Done

The solution to these challenges lies in the “One-and-Done” philosophy. Traditional machining often requires moving a part between multiple fixtures to reach different sides. Every time a worker moves the part, there is a risk of error. With 5-axis technology, we can machine five sides of a part in one clamp.

Furthermore, this technology allows for the use of shorter cutting tools. Because the tool can tilt toward the workpiece, it does not need to be as long to reach deep cavities. Shorter tools vibrate less and can cut faster. This leads to better surface finishes and longer tool life, which is critical for 5-axis cnc machining services aiming to keep costs down while maintaining quality.

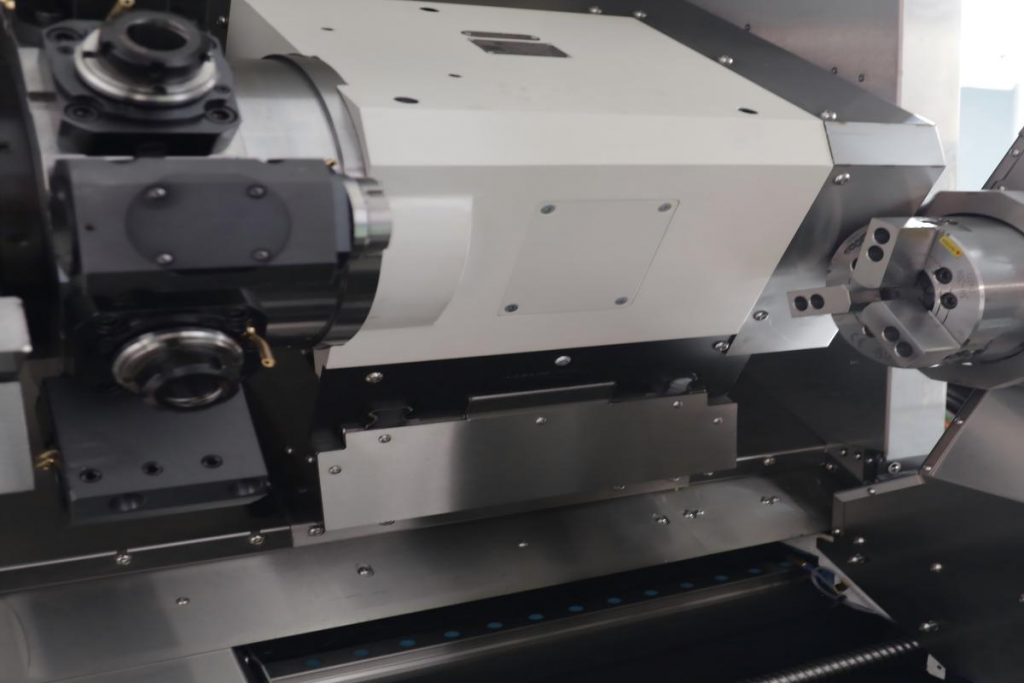

The Leichman 5-Axis Machining Center

At Leichman, we design our machines to tackle these exact problems. Our equipment acts as a compact powerhouse for high-value industries. We focus on rigidity and thermal stability, ensuring that our machines hold tight tolerances even during long production runs.

Our machines are built to support the complex movements required for impellers and medical implants. We integrate advanced control systems that manage the simultaneous movement of all five axes. This ensures that the tool point remains exactly where it needs to be relative to the workpiece.

Case Study: Precision Gears in Germany

A clear example of our technology in action occurred recently in Stuttgart, Germany. An automotive gear manufacturer needed to upgrade their core process for electric vehicle transmissions. They faced a significant challenge: producing hardened steel gear blanks with mirror finishes and micron-level consistency.

They chose our LKX1250 Five-Axis turn and mill center. This machine replaced two separate turning and milling stations. The results were impressive. The customer reduced their cycle times by 34%. More importantly, the machine maintained ±0.001° accuracy during complex undercuts. The automatic tool changer, holding 60 tools, allowed them to switch between roughing and finishing without stopping. You can read more about this success story here.

Work with Leichman

We believe that high precision should be accessible and reliable. Leichman combines advanced CNC innovation with a solid manufacturing legacy. We do not just sell machines; we provide complete solutions that solve production bottlenecks.

Our commitment goes beyond the sale. We offer rigorous quality control and dedicated support to ensure your production lines keep running. Whether you are machining aerospace turbine blades or medical implants, our goal is to give you the competitive edge you need. We invite you to explore how Leichman can transform your manufacturing process. Contact us to learn more about our solutions.