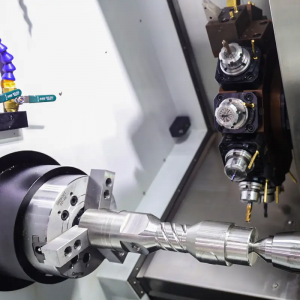

Leichman, a well-known sub-brand of Hoston, specializes in innovative CNC milling and turning centers that push the limits of precision and efficiency. One of our highlight products is the turn mill center with Y axis, a novel equipment that combines milling and turning capabilities. This article delves into what a turn mill center with Y axis is and the benefits it provides to modern production.

What is a Turn Mill Center with Y-Axis?

A turn mill center with Y-axis is a sophisticated machine that integrates both turning and milling capabilities into a single setup. Unlike traditional CNC milling and turning centers, which are often limited to either milling or turning tasks, our turn mill centers can perform both functions simultaneously. The addition of the Y-axis allows for increased flexibility in machining complex geometries and features. This capability enables manufacturers to produce intricate parts with high precision, reducing the need for multiple setups and enhancing overall productivity.

Advantages of the Y-Axis Functionality

The Y-axis functionality in our turn mill centers significantly expands the machining capabilities available to manufacturers. It allows for off-center milling operations, which means that users can access features on the sides of turned components without needing to reposition the workpiece. This versatility is particularly beneficial for small to medium-sized batches that require varied machining tasks. At Leichman, we understand that efficiency is key, and incorporating a Y-axis into our CNC milling and turning centers helps our clients achieve their production goals with fewer interruptions.

Streamlining Production Processes

One of the most significant benefits of using a turn mill center with Y-axis is the ability to streamline production processes. By combining milling and turning operations in one machine, manufacturers can reduce setup times and minimize handling of parts. This all-in-one solution not only saves time but also decreases the chances of errors that can occur during multiple setups. Our CNC milling and turning centers are designed with this efficiency in mind, allowing businesses to enhance their production workflows and ultimately improve their bottom line.

Conclusion

In conclusion, the turn mill center with Y-axis represents a significant advancement in CNC milling and turning technology. At Leichman, we are proud to offer these innovative machines that combine precision, flexibility, and efficiency. By integrating milling and turning capabilities into a single setup, our turn mill centers help manufacturers streamline their production processes and achieve high-quality results. As the manufacturing landscape continues to evolve, we remain committed to providing cutting-edge solutions that empower our clients to excel in their respective industries. With Leichman, you can trust that you are investing in the future of machining technology.