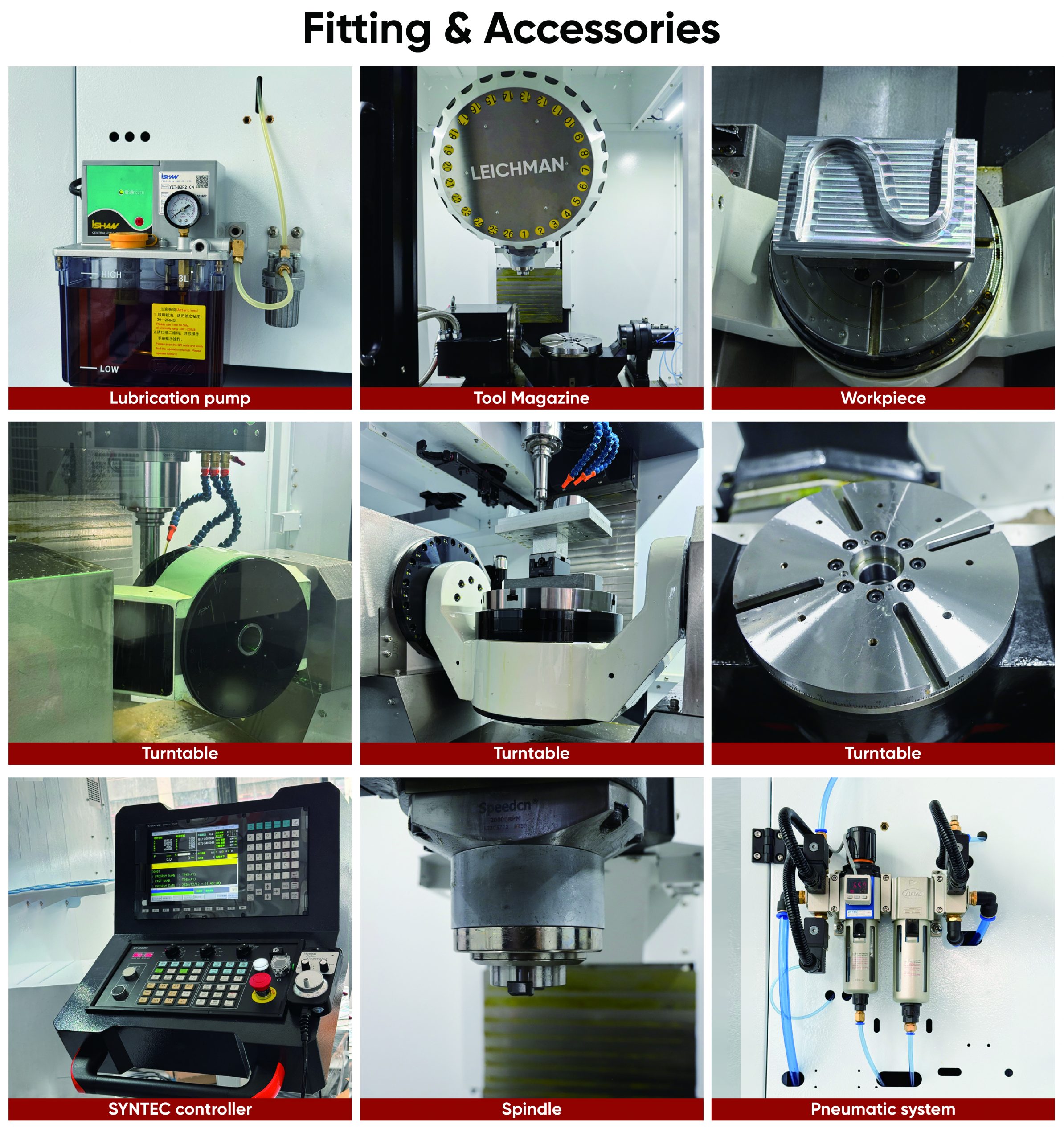

A cost-effective CNC machine tool designed for high-precision, high-productivity machining of complex parts across industries such as automotive, aerospace, electronics, molds, and instrumentation.

Key Capabilities:

- Multi-Process Integration: Supports drilling, reaming, boring, tapping, milling, and more in a single setup, eliminating the need for special fixtures and marking processes.

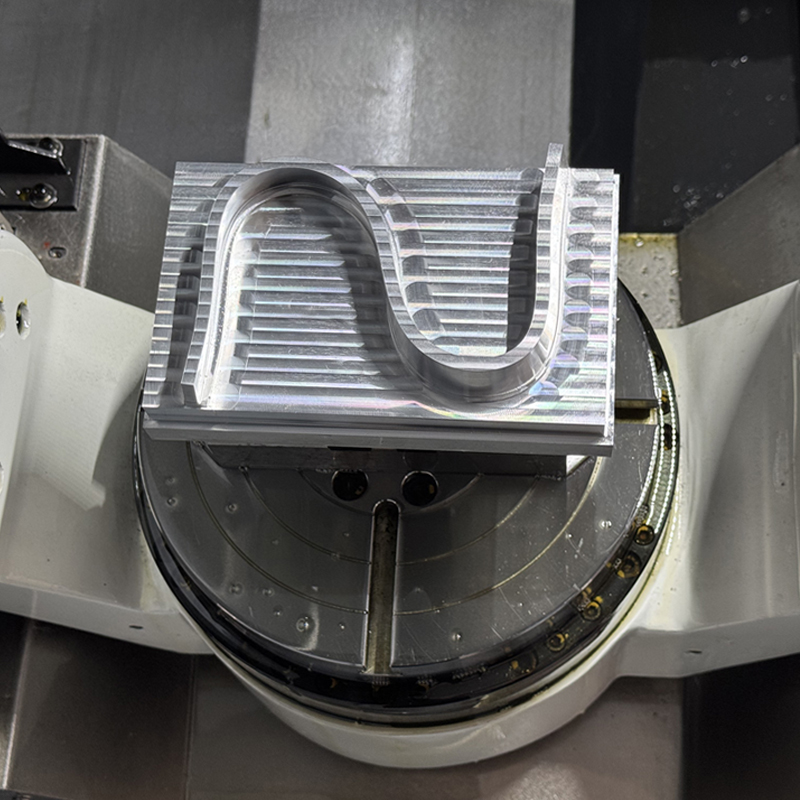

- Wide Applicability: Ideal for machining medium/small discs, plates, shells, valves, cams, and other components with high hole-position accuracy.

- Automation & Efficiency: Programmable processing reduces manual labor, shortens production cycles, and enhances consistency.

Key Features:

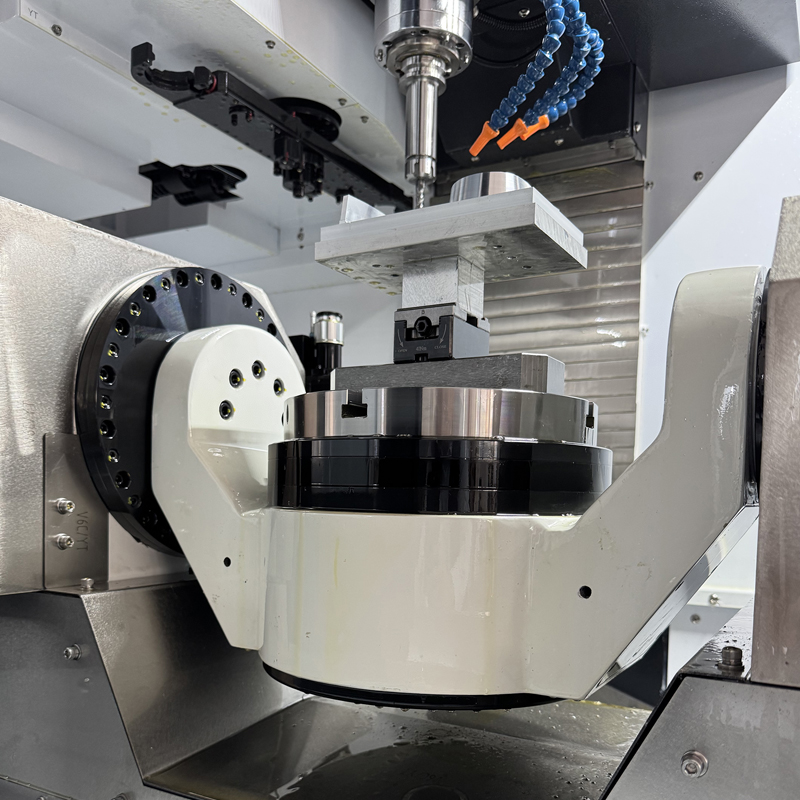

- Five-Axis Flexibility: Enables complex multi-face machining in a single clamping.

- High-Performance Spindle: Equipped with a Taiwanese-made spindle offering strong broaching force, durability, and reliability.

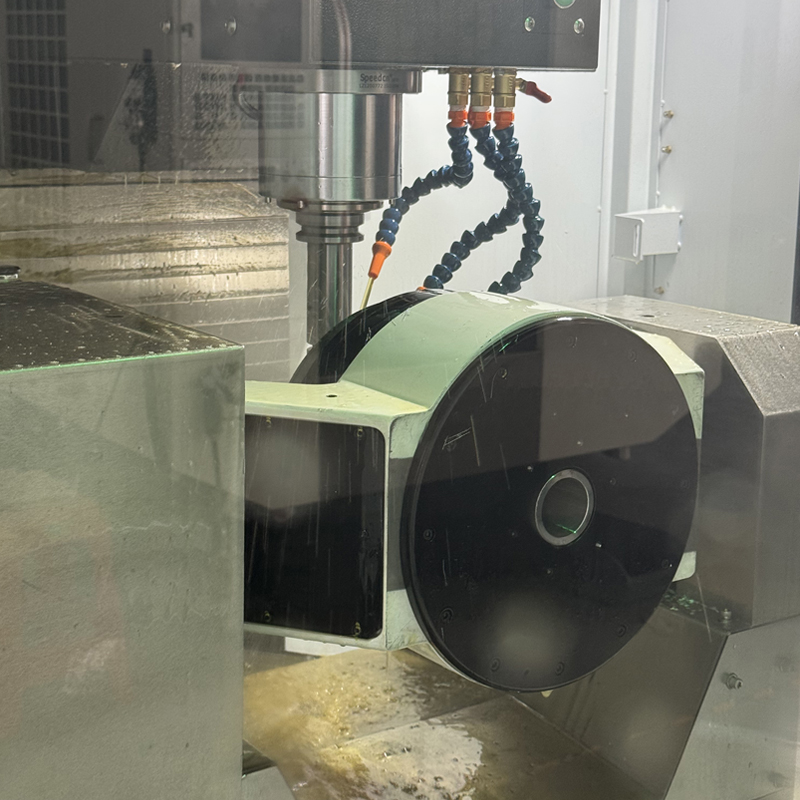

- Full Protection Cover: Prevents cutting fluid and chip splashing while ensuring an aesthetic appearance.

Advantages:

- Improves machining accuracy and productivity

- Reduces operator workload and production time

- Suitable for diverse industries and complex part geometries